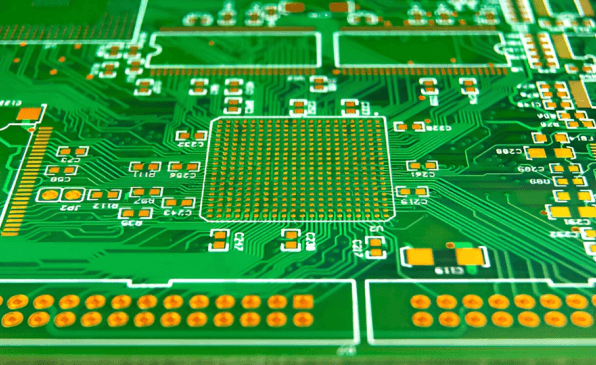

In the world of electronics manufacturing, FR4 PCB stands out as one of the most widely used and versatile printed circuit board types. Known for its excellent strength, durability, and electrical insulation properties, FR4 PCB has become the foundation for countless electronic devices — from simple gadgets to high-performance industrial systems. Its balance of affordability, mechanical stability, and thermal resistance makes it a preferred choice across nearly every industry.

What Is an FR4 PCB?

The term FR4 refers to a grade of flame-retardant fiberglass-reinforced epoxy laminate material. The “FR” stands for Flame Retardant, while the number “4” denotes the specific type of material in this category. This material is used as the substrate or base layer in most standard printed circuit boards.

An FR4 PCB consists of layers of woven fiberglass cloth impregnated with epoxy resin, which are laminated together with one or more copper foil layers. The result is a rigid and robust structure that provides both mechanical support and electrical insulation for the circuitry. FR4 PCBs can be single-sided, double-sided, or multilayered, depending on the complexity of the design and the application.

Key Properties of FR4 PCB

One of the main reasons FR4 PCB is so widely adopted is because of its combination of mechanical strength, low cost, and stability. Some of its key properties include:

- High Dielectric Strength: FR4 material provides excellent electrical insulation, ensuring minimal current leakage and strong signal integrity.

- Thermal Resistance: The typical glass transition temperature (Tg) of FR4 ranges between 130°C and 180°C, allowing it to withstand standard soldering processes and moderate heat levels.

- Mechanical Stability: The epoxy-fiberglass combination ensures rigidity and dimensional stability, even under mechanical stress.

- Moisture Resistance: FR4 laminates are highly resistant to moisture absorption, preventing electrical failures in humid environments.

- Cost Efficiency: Compared to high-performance materials like Rogers or Polyimide, FR4 offers an economical solution without compromising quality for most applications.

These characteristics make FR4 PCB a dependable option for both consumer electronics and industrial systems.

Types of FR4 PCB

While FR4 is a standard material, it is used in different PCB configurations based on circuit complexity and performance needs. Common types include:

Single-Sided FR4 PCB: Features copper traces on one side of the FR4 substrate. It’s ideal for low-cost, simple circuits such as power supplies and LED modules.

Double-Sided FR4 PCB: Has copper layers on both sides, allowing more complex routing and component placement, commonly used in control panels and automotive electronics.

Multilayer FR4 PCB: Composed of multiple layers of FR4 and copper stacked together, enabling high-density circuit designs. These are used in smartphones, computers, and communication systems.

High-Tg FR4 PCB: Designed for high-temperature applications, this variation uses a higher glass transition temperature resin system for enhanced performance and durability.

Applications of FR4 PCB

The versatility of FR4 PCB makes it suitable for a wide range of industries and devices. Common applications include:

- Consumer Electronics: Mobile phones, televisions, audio systems, and computers rely on FR4 PCBs for stable operation.

- Automotive Systems: Used in dashboard electronics, lighting systems, and control units due to its mechanical reliability and vibration resistance.

- Industrial Equipment: Found in automation controllers, power converters, and sensors where durability is critical.

- Telecommunications: FR4 boards are used in routers, antennas, and signal processors thanks to their electrical insulation properties.

- Medical Devices: Many diagnostic and monitoring devices employ FR4 PCBs for dependable circuit performance.

The Manufacturing Process of FR4 PCB

The production of FR4 PCB involves several precise and controlled steps to ensure accuracy and quality:

- Design Layout: The PCB layout is created using CAD software to define circuit traces and component locations.

- Material Preparation: Sheets of FR4 laminate are cut to size and cleaned to ensure a smooth bonding surface.

- Copper Lamination: Copper foil is laminated on one or both sides of the FR4 material under heat and pressure.

- Imaging and Etching: A photoresist pattern is applied to the copper layer and exposed to UV light. The unprotected copper is then chemically etched away, forming circuit traces.

- Drilling: Holes are drilled for through-hole components and vias to connect different layers.

- Plating: The drilled holes are plated with conductive material to create electrical pathways between layers.

- Solder Mask Application: A solder mask layer is added to protect copper traces from oxidation and solder bridging.

- Silkscreen Printing and Surface Finish: Labels and component markings are printed, followed by surface finishes such as HASL, ENIG, or OSP to improve solderability.

- Inspection and Testing: Each FR4 PCB undergoes electrical testing to ensure it meets design and performance standards.

This comprehensive process ensures the PCB is reliable, durable, and ready for component assembly.

Advantages of FR4 PCB

The popularity of FR4 PCB stems from its broad range of benefits:

- Versatility: Suitable for nearly all electronic devices and systems.

- Durability: Excellent mechanical strength and wear resistance.

- Thermal Stability: Can endure standard soldering and assembly processes.

- Consistency: Provides uniform electrical properties across the board.

- Affordability: Offers an ideal balance of cost and performance.

Because of these attributes, FR4 continues to dominate PCB fabrication globally, serving as the industry’s standard substrate.

Limitations of FR4 PCB

While FR4 PCBs are highly reliable, they are not suitable for every application. High-frequency or high-speed circuits may experience signal loss or dielectric inconsistencies with FR4. For such cases, advanced materials like PTFE (Teflon), Rogers, or Polyimide laminates are preferred. Similarly, in environments exceeding 180°C, FR4 may lose structural integrity, making high-Tg or metal-core alternatives more suitable.

Future Trends in FR4 PCB Technology

With the growing demand for compact and efficient electronics, FR4 PCB manufacturing is evolving to meet new technological standards. Miniaturised designs, HDI (High-Density Interconnect) structures, and lead-free processes are becoming mainstream. Manufacturers are also adopting eco-friendly materials and processes to comply with RoHS and REACH standards, ensuring sustainability without compromising performance.

Conclusion

In conclusion, the FR4 PCB remains the cornerstone of electronic circuit design and manufacturing. Its exceptional balance of mechanical stability, thermal resistance, and cost-effectiveness ensures it continues to be a top choice for engineers and manufacturers across diverse industries.

If you’re seeking reliable quality and performance, partnering with a trusted FR4 PCB Supplier is essential. A professional supplier can provide high-grade materials, precision manufacturing, and customised FR4 PCB solutions that meet your exact design and application requirements — ensuring your electronic products achieve superior performance and long-term reliability.